- Quanta & Qualia

- ZOEK gGmbH

Next Generation Human Computer Interaction Solution

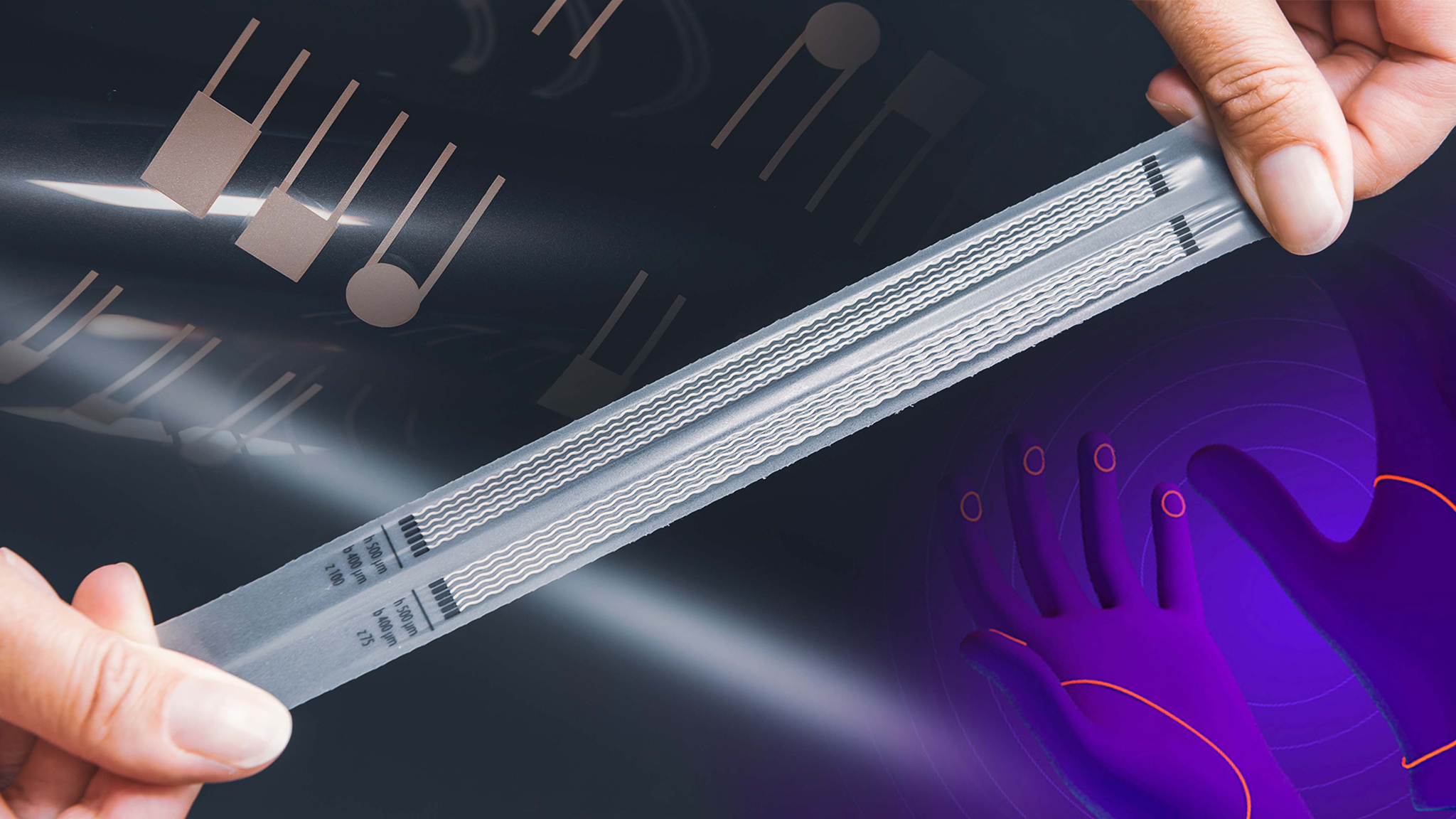

Thanks to the support of SmartEEs, the ZOEK gGmbH is developing haptic solutions and is investigating flexible printed cabling (FPC) to be integrate in the Magos gloves, the next generation wearable input device. At Magos the focus is the development of a novel Human Computer Interaction (HCI) solution which will revolutionize the interaction framework within XR environments.

Solar Foil for the Internet of Things

Cost-effective and ubiquitous power generation through lightweight, flexible and printed solar foils opens up a variety of new applications from small self-sufficient systems (Internet of Things) up to electro-mobility. In order to secure the growing demand for solar foils in the future, roll-to-roll manufacturing processes as well as scalable solar modules have to be developed. This is the leading goal in this project. In addition, fundamental questions have to be answered. This includes cell architecture, material development and optimized process parameters.

Intelligent Surfaces for the Future

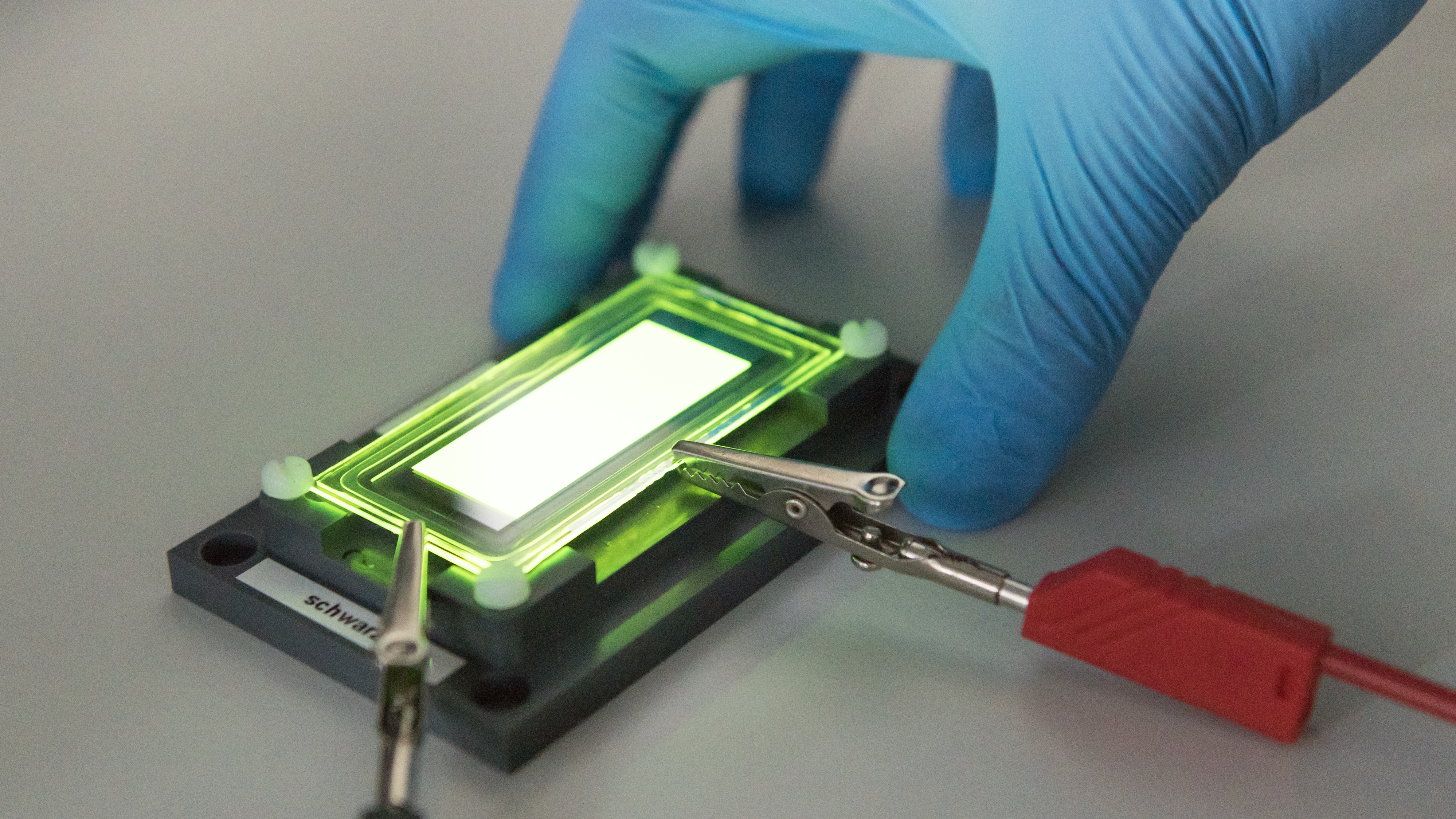

Project FIMO laid the cornerstone for this project. By now, the integration of organic light emitting diodes (OLED) by film-insertion-molding will be taken to the next level. Using new materials, flexible substrates, and a superior encapsulation technology, OLED will be integrated jointly with touch controls into a robust plastic component having all functions incorporated and combining intelligent surfaces with 3D design.

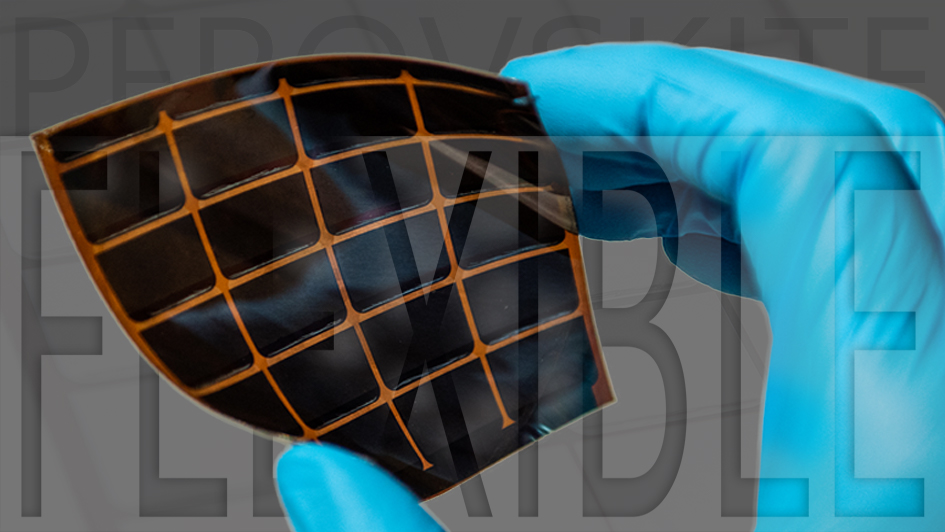

Perovskite-type Solar Cells

Clean, affordable, and unlimited energy is essential for all of us, but still is a challenge. Perovskites are promising materials for solar cells having a high degree of efficiency and the potential for roll-to-roll manufacturing. The challenge of this project is to develop a reliable and reproducible high-yield process and, in parallel, substitute the presently required lead by an environmentally more friendly metal. In this manner we create large area, environmentally friendly, and low cost solar cells to yield clean energy.

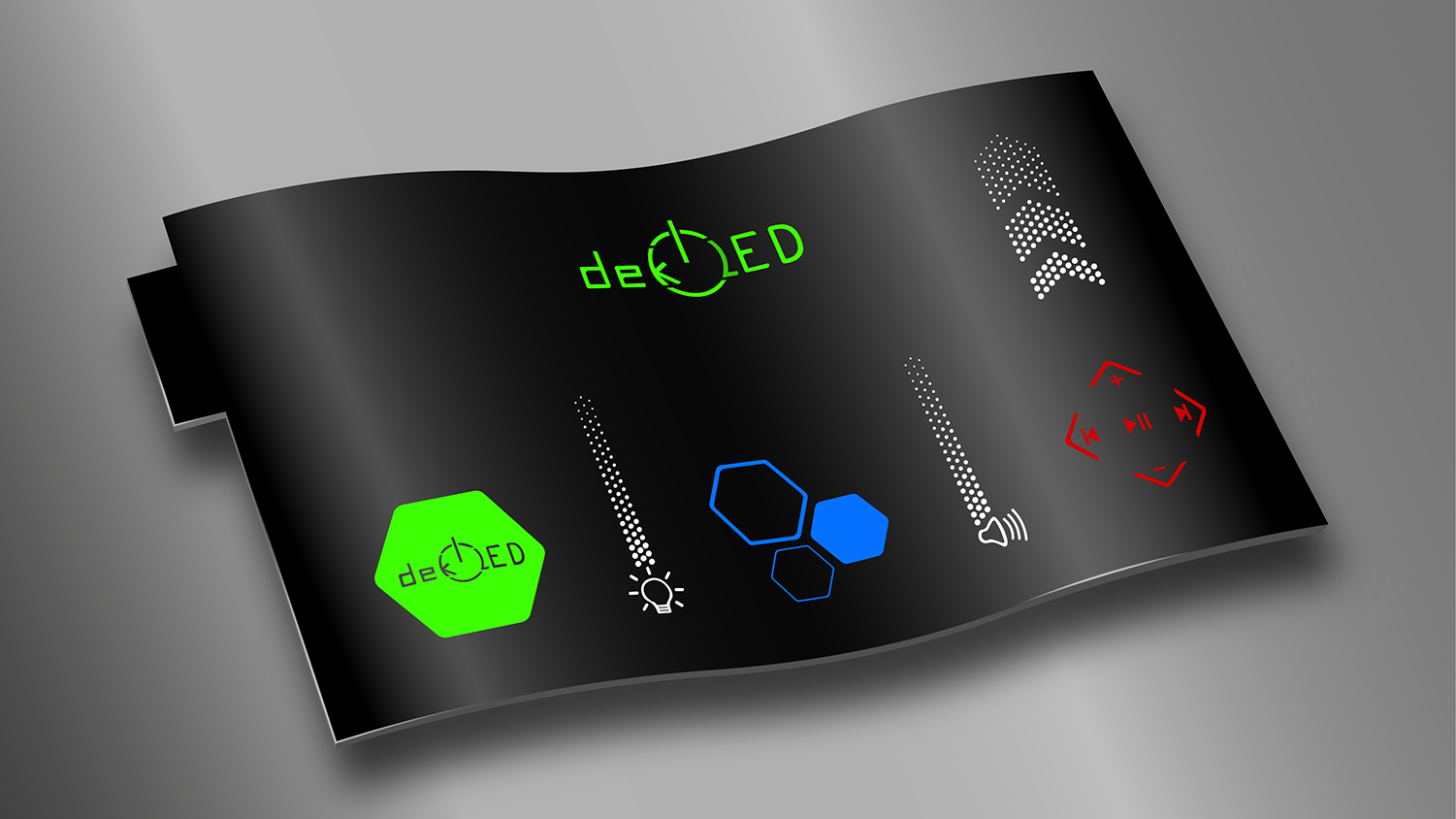

OPE Technology and Decorative Surfaces Merge

Future operating controls are standardized, elegant, and hidden. Bulky buttons and controls will be obsolete. With OPE the future starts today. By film-insert-molding (FIM), integrated controls with complex functions became available which unify thin, planar, and lightweight organic light emitting diodes (OLED) and solar cells with touch controls in a single part. Compact, light, and robust plastic components now emerged for automobiles, household goods and other electronic devices.

A close look at printing and coating organic layers

Coating, printing, go – is it this simple? OPE requires complex layer structures and patterns, and in most layers each nanometer has to be taken into consideration. But what happens, if one layer is printed on top of the previous layer? Do materials mix and if so, how strongly? Answers on these question pave the way for a better understanding and reproducible OPE manufacturing processes.

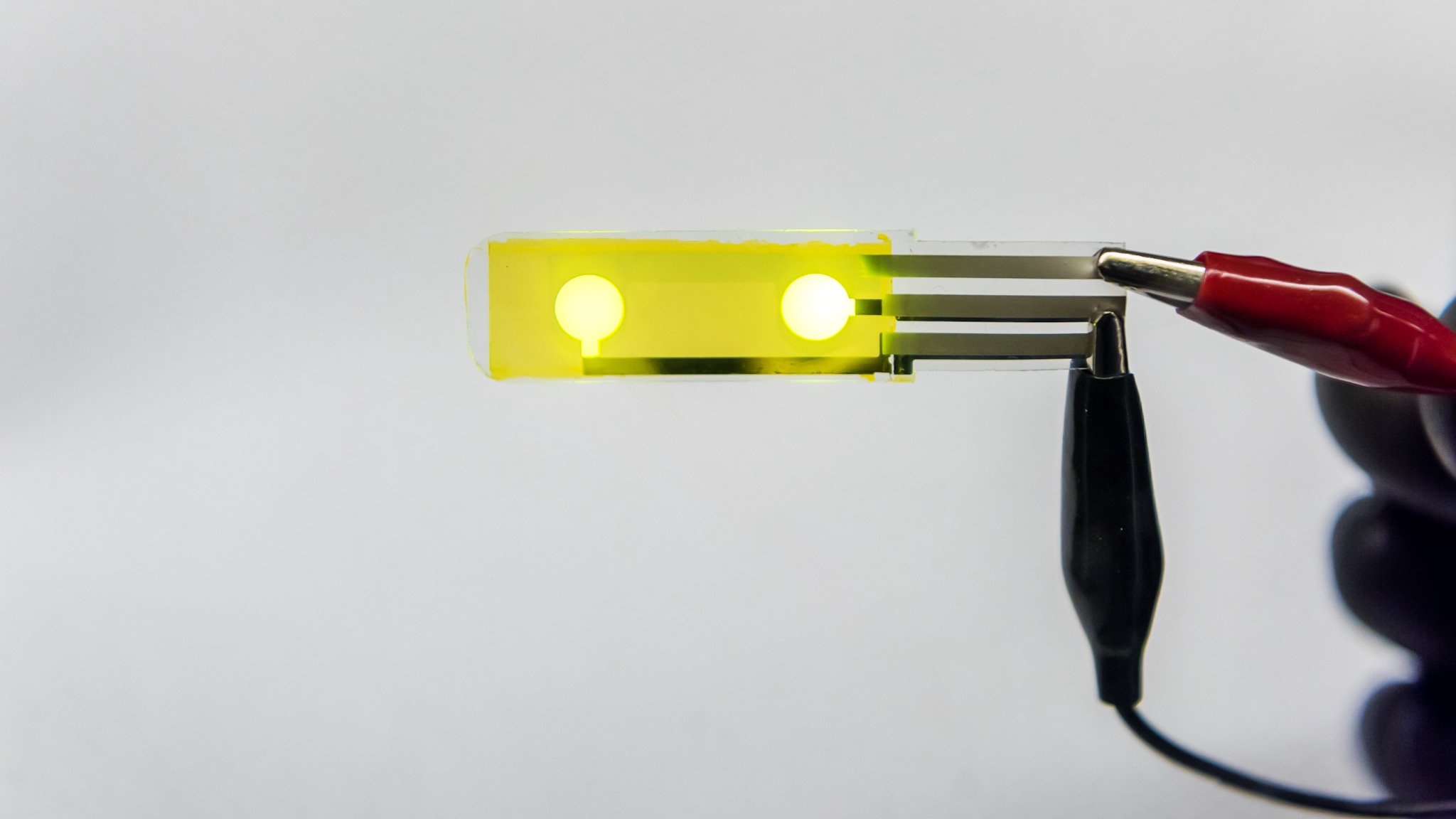

A Technical Revolution for the Mass Production of OLEDs

In tomorrow’s world, OLEDs are mass manufactured in a cost-efficient and ecologically sound way. They are lightweight, flexible, and revolutionize the future’s light design. This was the scope of the project ecOLED. Within this project we first time applied a process which proved its suitability in the production of photographic films. This process allows to coat several material layers in one step in a roll-to-roll-manner.

![[Translate to English:] Bedienelement FIMO](/fileadmin/user_upload/06_Forschungsprojekte/Fimo_02.jpg)